Stock Code: 300855

Stock Code: 300855

Technology Center

The center has a research and development team and professional testing rooms. There are high-temperature alloy pilot production line and advanced domestic and oversea testing and analysis instruments. There are more than 20 people with level II qualification certificates and 6 people with level III qualification certificates in Technology Center, who are capable of physical and chemical inspections (including mechanical tests, chemistry tests, metallographic analysis, etc.) and non-destructive tests (including UT, X-ray, fluorescence detection, etc.), and can carry out various physical and chemical test analysis and non-destructive testing according to national and international test standards, such as ASTM, GE, Nadcap, European EN, and international ISO standards.

High-temperature alloy pilot production line

Used for pilot test of high temperature alloy materials.

25KG VIM Furnace

500KG VIM Furnace

Mechanical testing

Mechanical properties items: high temperature/room temperature tensile test, room temperature/low temperature impact, brinell/rockwell/vickers hardness, high temperature creep and rupture test, etc.;

Process performance items: flaring, flattening, twisting, bending, winding, etc.

Tensile test machine

High temperature creep and rupture test machine

Impact test machine

Elemental Testing

Use various instruments or wet analysis to test the element content of metal materials.

Oxygen/Nitrogen/Hytrogen analyzer

Fluorescence spectrum analyzer

Atomic absorption analyzer

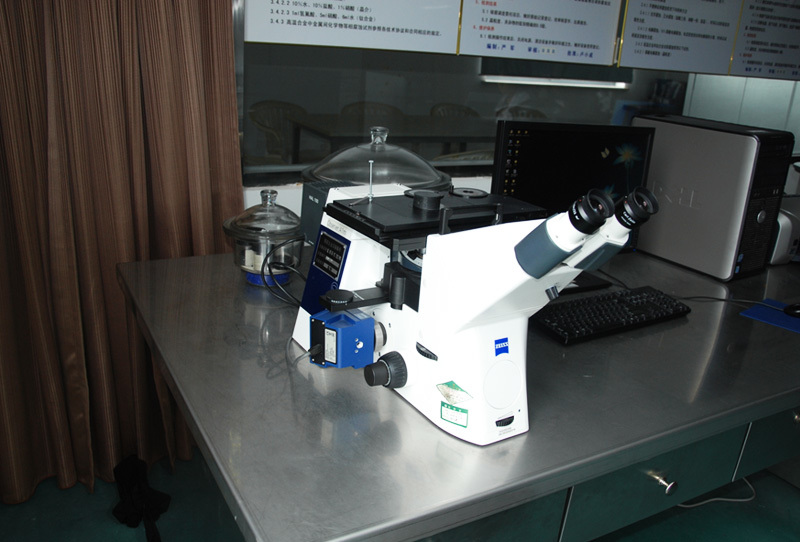

Metallographic analysis

Test and analyze the structure and quality of steel and alloy materials.

Zeiss microscope

Zeiss stereomicroscope

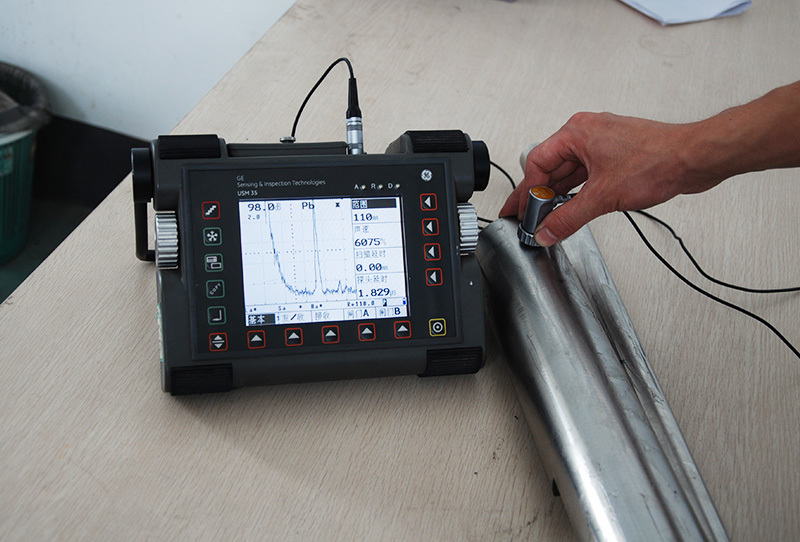

Non-destructive testing

Analyze and test the intrinsic and surface defects of various metal materials through ultrasonic flaw detection, fluorescence penetration, X-ray, eddy current detection, color flaw detection, etc.

Ultrasonic digital wave flaw detection

Ultrasonic online flaw detection

Fluorescence penetration testing line

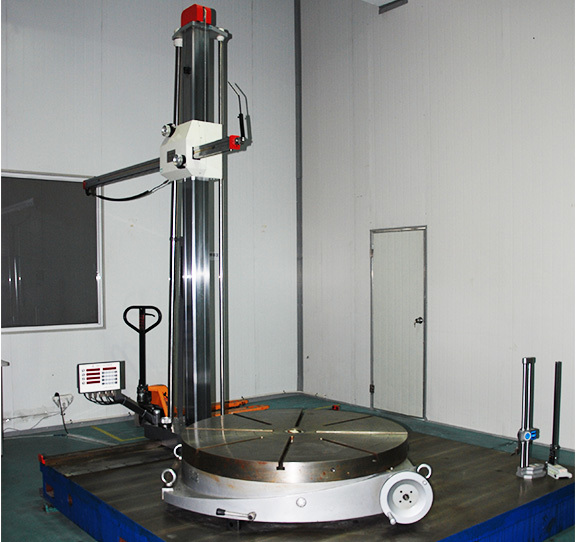

Dimensional inspection

Marking machine

CMM

CMM